The company Dünnewald Stahlhandel GmbH & Co. KG from Münster has been at home in the steel and steel processing business for more than 180 years. The product range consists of rolled steel, bright steel, stainless steel, reinforcing steel and Hardox. The customised processing of the materials takes place by laser cutting, flame cutting, reinforcing steel processing, sawing and blasting. A restamping licence is also available.

In the past, hand-operated stamps were used for restamping and marking a wide variety of materials. This time-consuming and accident-prone method should be replaced.

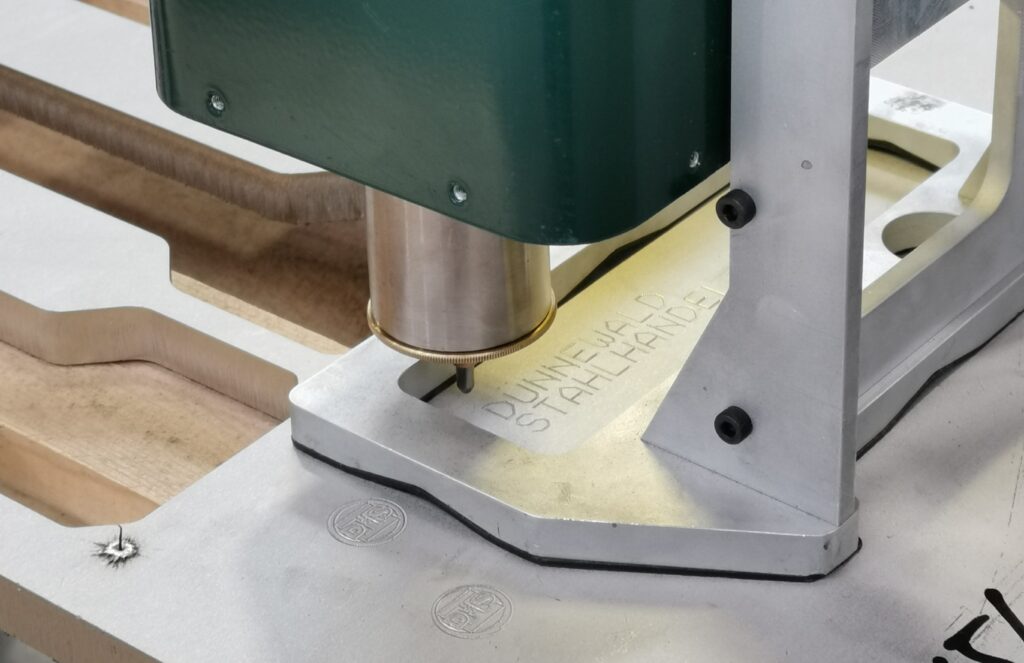

The machine was selected during a demonstration in Münster together with the future machine operators. A Marktronic Portadot 130×30 with 4000 controller was suitable for all applications due to its impact and speed. The flexibility, the simple programming and the purely electrical operation of the dot marker were further advantages. The machine could be operated by all employees after a short training. With the logo editor, the restamping and company logos were programmed and stored in the controller. Only the individual markings have to be programmed or scanned. The markings are even and are made on materials up to 62 HRc.

The Portadot 130×30 is used for restamping and for marking for traceability. The marking can be done on all existing materials and is clearly visible even after sandblasting. The customer is very satisfied with the result.