Quality, that shapes!

About us

Our history

Röltgen – Quality, that shapes!

Under this motto, we have been producing marking tools and machines as well as tablet presses for the most demanding customers in the world for over 80 years.

Years

Experience

We have been producing for the world's most demanding customers for over 80 years.

%

More than

Delivery date reliability

Rely on us - on-time deliveries guaranteed!

%

Less than

Complaints

Quality made in Germany

Savings

Kilograms CO²

Since 01.01.2015, Röltgen has been heating in a climate-neutral manner and generates approx. 75% of its electricity needs itself.

Quality, that shapes!

Our Team

Frank Baehr

CEO

He is one of our managing directors and your contact person for purchasing.

Andreas Bußmann

Sales Field Service

Mr. Bußmann looks after our customers north of the Ruhr area as far as Berlin. On request, he also demonstrates our machines on site.

Stephan Weiß

Operations Manager

Mr. Weiß is mainly responsible for our work preparation and calculation. But he will also be happy to help you with technical questions about marking.

Marc Baehr

CEO

Your contact person in sales, for the field service in the eastern and southern federal states and our second managing director.

Stefan Kuschmierz

Operations Manager

Our major project manager and expert for FlexiTab tablet presses will be happy to answer any technical questions you may have. Mr Kuschmierz also carries out the annual calibration of our FlexiTab XL.

Jörn Dorfmüller

Sales Field Service

If you need advice or a demonstration in and around North Rhine-Westphalia, Mr Dorfmüller is your contact. He will help you competently and reliably on site.

Uwe Bittlingmayer

Sales

His calm and professional manner is much appreciated by our customers. Even in hectic times, he enjoys his work and advises you competently on all questions of marking.

Quality, that shapes!

Under this motto, we have been producing embossing tools and machines as well as tablet presses for the most demanding customers worldwide for over 80 years.

Founded in 1941 by Mr Paul Röltgen, our company began by producing hand-operated stamps in all designs. The early years were marked by war, and production had to be halted in 1944 due to the war. Slowly, the misery into which fascism had plunged Germany and the world became apparent.

After the terrible war was lost and peace returned, the period of reconstruction began in Germany. Paul Röltgen reopened his workshop after the currency reform in 1949 and began manufacturing hand stamps again. Röltgen quickly became known among Solingen steel manufacturers as a quality supplier. This did not go unnoticed, of course, and soon Paul Röltgen was supplying his goods to many well-known companies throughout Germany and then all over the world. Naturally, the workforce also grew steadily.

The second generation

With the arrival of the second generation, daughter Gabriele and son-in-law Siegfried Baehr, and the construction of the company’s own building in Solingen Merscheid, the product portfolio was quickly expanded and the customer base enlarged. In addition to hand stamps and embossing tools, the first marking machines were traded and later also designed, built and distributed by the company itself.

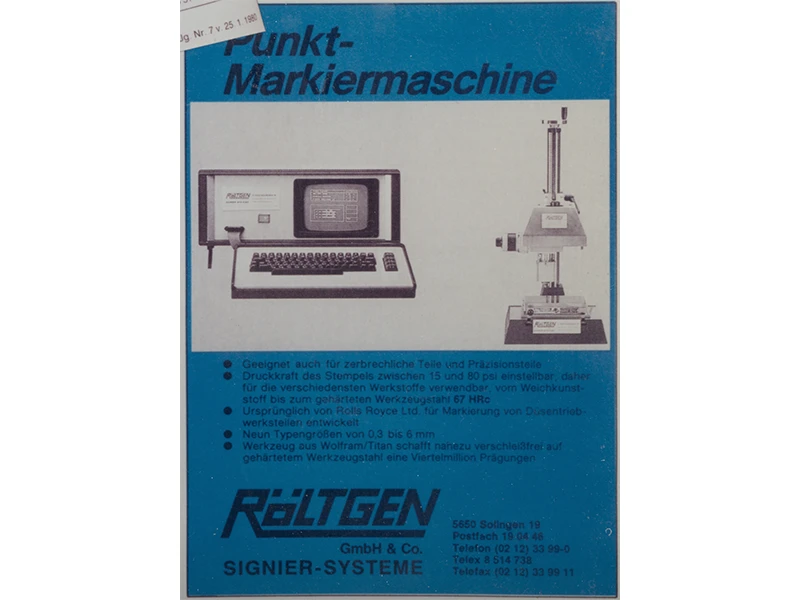

In 1983, a partnership was entered into with Edward Pryor Ltd. from Sheffield, which was the first company to offer computer-controlled dot marking machines on the German market. This made it possible for the first time to program individual markings on a computer and apply them to almost any material. Laser marking was added in the 2000s.

In 1991 and 2008, the company premises were significantly expanded and modernised.

The third generation

The third generation is now at the helm: Mr Frank Baehr joined the company in 1995 and Mr Marc Baehr in 1997. They have been managing directors of Röltgen GmbH & Co. KG since 2007 and are proud of their 41 employees, many of whom they trained themselves.

Production takes place exclusively in Solingen, Germany. Röltgen attaches great importance to providing qualified vocational training for its own apprentices (approx. 10% of the workforce) and regular further training for its mostly long-standing employees. We work closely with schools and universities to promote young talent before and during their training.

Röltgen marking systems are used in the automotive and aviation industries, in steel and mechanical engineering, and in modern packaging machines in the pharmaceutical, food and cosmetics industries. In addition to the extensive standard range, approximately 80% of production consists of special and custom-made products.

Sustainability

It is no coincidence that the entire production process is geared towards sustainability and the responsible use of the environment and resources. Röltgen was already a pioneer 30 years ago with an efficient cleaning system for electroplating wastewater. In addition, there is a 30,000-litre rainwater collection system for industrial water use in the company and a 700-square-metre photovoltaic system, which is used for modern machinery that also meets ecological requirements.

Since 2015, Röltgen has been sourcing its remaining electricity requirements exclusively in the form of green electricity, and the gas used for heating is CO2-compensated. By converting all lighting to LED technology, electricity consumption has also been significantly reduced.

As you can see, Röltgen is fit for the future and we look forward to a good partnership with you.

1941

Foundation of the company on 08.01.1941 by Mr Paul Röltgen.

1945

A new beginning on Gräfrather Strasse in Solingen.

1952

Move to larger premises on Friedrich-Ebert-Straße in Solingen.

1961

New construction of the company’s own building on Harzstraße in Solingen.

1965

The second generation joins the company: Mrs Gabriele Röltgen.

1967

Siegfried Baehr joins the company. 1968 Marriage of Siegfried Baehr and Gabriele Röltgen.

1971

First expansion of operations on Harzstraße in Solingen.

1983

German premiere of the first computer-controlled dot-marking machine.

1991

50th anniversary! What a great experience.

1991

Second company expansion on the Harzstraße in Solingen.

2000

Renaming of Harzstraße to Paul-Röltgen-Straße.

2001

Development of the first tablet press: the FlexiTab XL.

2006

Construction of the first photovoltaic plant.

2007

Frank and Marc Baehr take over the management of the company.

2008

Third company expansion on Paul-Röltgen-Straße.

2014

Extension of the photovoltaic system.

2015

Conversion of all lighting to LED.

2016

75th anniversary! The legendary party on the “beach”.

2018

The second generation of the FlexiTab XL is presented.

2022

Launch of the machine parts and moulds product range

2025

The specially developed fibre laser for type plates is presented.

let’s get connected

Do you have a question?

Benefit from our many years of experience and let us advise you in person about your individual use cases.