Embossing tool DK12 / DK18

Mark products in the machine tool quickly, efficiently and without an extra work step.

This embossing tool was developed for marking workpieces directly on machine tools. The marking is performed quickly, clearly and geometrically correctly by the machine tool and is part of the normal production process, which reduces marking costs and avoids potential errors.

- Designed for use on CNC machining and turning centres as well as on manual turning, milling and drilling machines.

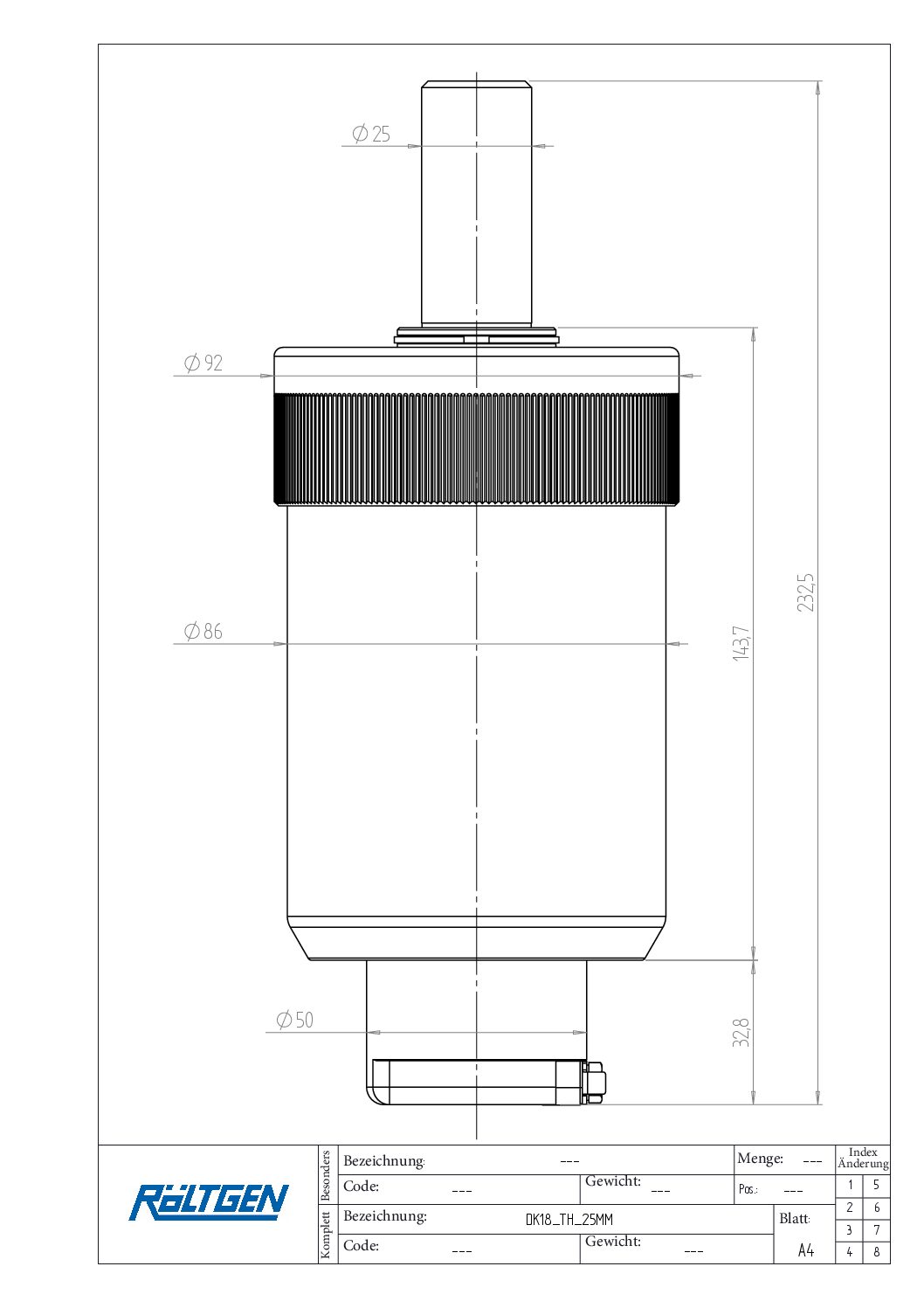

- Shaft sizes: diameter 20 mm and 25 mm, ISO 40 and 50, BT 40 and 50.

- Integrated type holder for holding steel types or customer-specific stamps.

- Additional type holders available as accessories.

Its efficiency, user-friendliness and low price make the embossing tool the most economical and advanced choice compared to conventional marking techniques.

- Easy positioning in the tool magazine or turret without affecting machine parts or workpieces

- Multiple positions for letters and numbers – up to 15 mm font height, depending on the material

- Adjustable and uniform marking depth

- Precise repeat accuracy of the marking position

- Quick replacement during production changes

- Sealing against the ingress of coolant and chips

Workflow: After inserting the desired numbers and/or letters into the holder, the embossing head is clamped into the tool holder. The tool holder then presses the embossing head against the workpiece. This tensions a spring assembly inside the head. With an adjustable force, the spring assembly relaxes and strikes the characters into the material. Depending on the material and the desired embossing depth, the spring tension can be adjusted by turning the head.