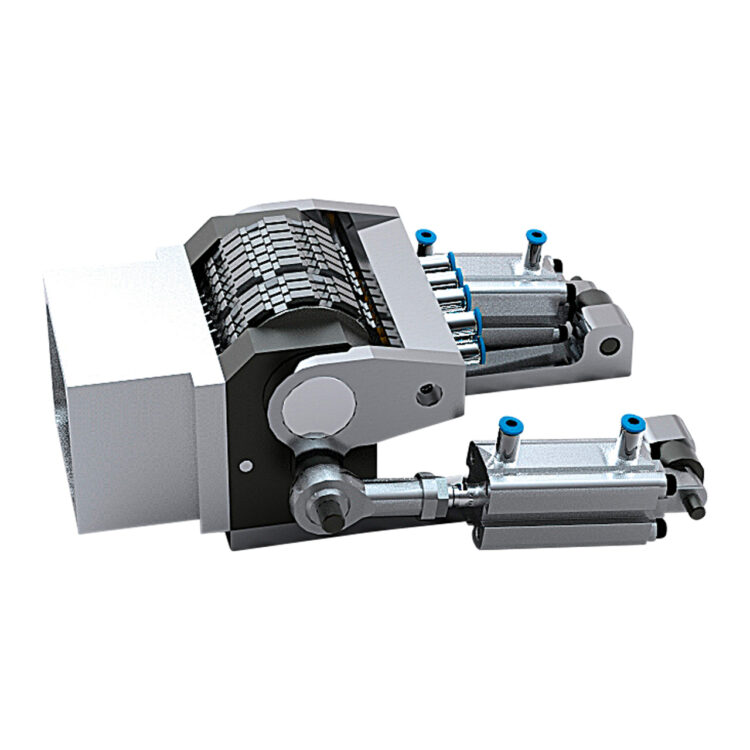

Computer controlled numbering head

Our computer-controlled numbering head offer a modern and highly precise solution for industrial marking. They operate independently or can be directly integrated into existing production lines. Thanks to the option of controlling them via PLC, they can be flexibly adapted to almost any automation environment.

These systems are suitable for both the lift embossing process and the roll-off process. They thus cover a wide range of applications – from logos and numbers to complex combinations of letters and special characters. The embossing machines can also be designed for hot embossing up to 900°C, offering maximum flexibility for demanding materials.

Possible applications

The computer-controlled embossing units are ideal for:

- Embossing on flat surfaces

- Serial numbers, batch codes and alphanumeric markings

- Logos, symbols and special characters

- Inline marking in automated manufacturing processes

- Hot stamping on thermally deformable materials

- Force- or roll-based embossing processes

They can be installed in roll-off and force presses of all kinds. In addition, all tools are also available in a hot stamping version and can be individually configured.

Fully automatic numbering mechanism – prepared for electronic control

The integrated numbering mechanism operates fully automatically. A pneumatic switching cylinder ensures safe and precise switching of the wheels.

As the system is already prepared for electronic or PLC control, it can be easily integrated into modern production lines.

Optional features

Digit heights

1.0 to 13 mm – suitable for different requirements in terms of legibility and material thickness.

Number of digits

1 to 50 digits – ideal for short codes or long series designations.

Engravings (10 standard positions)

0–9, additional engravings or special characters available on request.

Engraving variants and fonts – the right solution for every application

We offer different engraving variants depending on the material and requirements:

- Sharp engraving – for metal embossing

- Flat engraving – optimised for hot stamping

- Rounded – minimises notch effects

- Point engraving – reduces the embossing force required

- Digital engraving – particularly suitable for subsequent inspection by camera

Special bearings – less wear, less sticking

The embossing wheels are constructed with special bearings that reduce sticking due to oil or dirt. This design increases service life and ensures trouble-free operation even under difficult production conditions.

Technical advantages at a glance

- Selective individual wheel control

- Adjustment of an 11-piece character set in less than 5 seconds

- Each wheel switch is monitored – incorrect switching is registered

- Separate query of the zero position as a reference point

- Press stroke is registered to prevent switching in crash position

- Monitoring of crank movement – process deviations are corrected

These functions ensure maximum process reliability and the highest precision.

Designs according to customer requirements

We manufacture our computer-controlled embossing machines:

- according to customer-specific requirements,

- according to drawings,

- according to sketches

- or according to samples.

This means you receive a tool that is precisely tailored to your production, your material and your marking specifications – integrated, inline-capable and self-sufficient.

Conclusion – Precise, flexible and perfect for automated processes

Computer-controlled numbering heads offer maximum accuracy and high process reliability. They are ideal for automated production lines and enable sophisticated marking solutions, from standard embossing to hot embossing at up to 800°C.

Thanks to their flexible configuration and PLC control, they adapt precisely to your manufacturing process – quickly, reliably and durably.

View in catalog