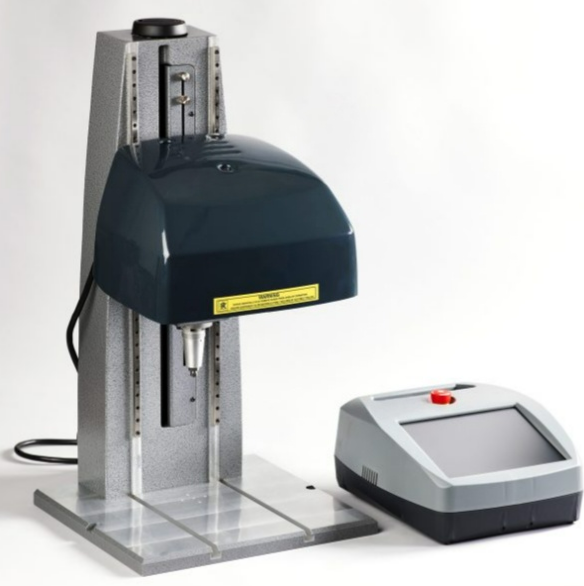

Marktronic BenchScribe 4000

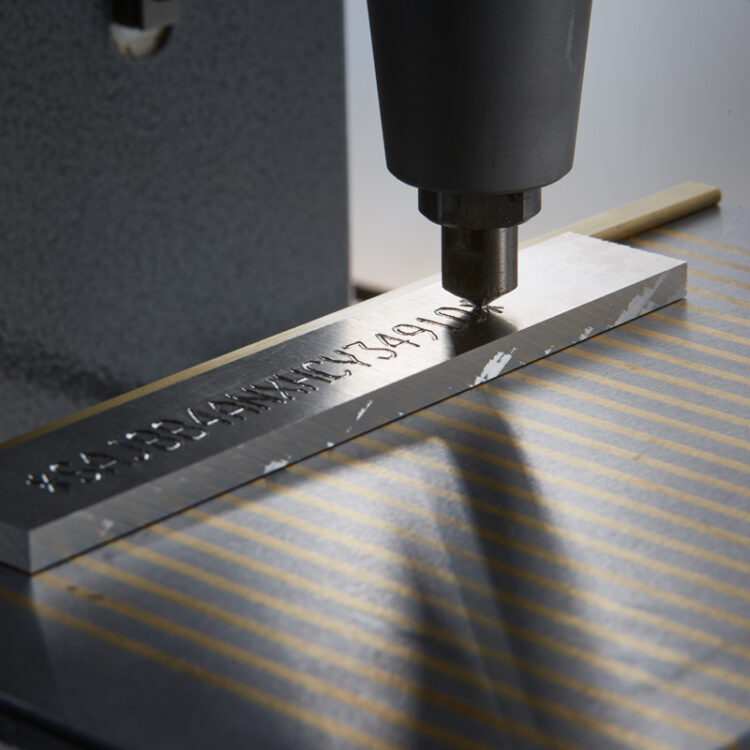

The scribe marker BenchScribe is a powerful, compact scribing machine that produces continuous, clean lines on flat surfaces and large-diameter components. This benchtop machine is specifically designed for marking small to medium quantities in workshop and manufacturing environments and offers exceptionally high marking quality.

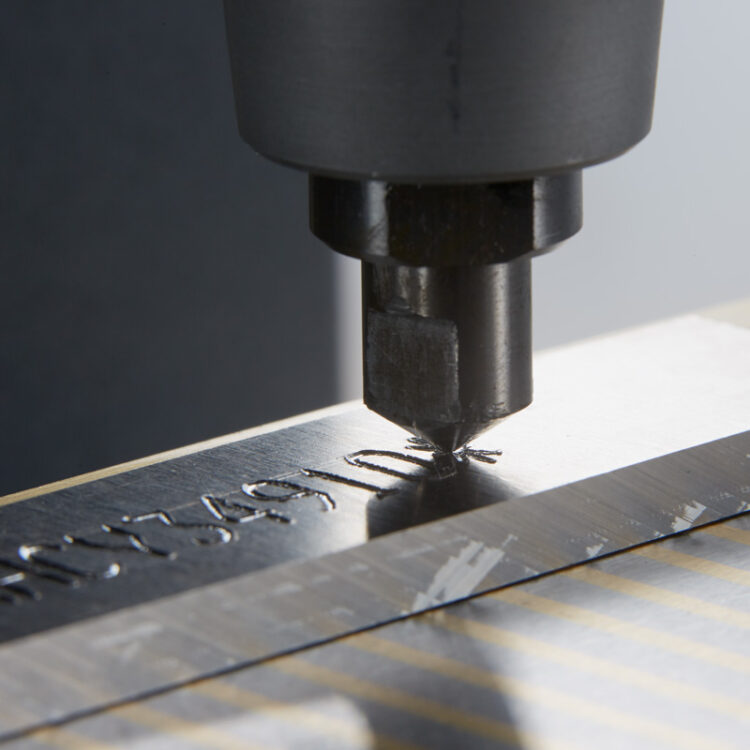

The clear, precise line engraving makes the BenchScribe the preferred choice for particularly fine markings – such as serial numbers, logos, technical data or VIN marking in the automotive industry. The continuous line creates a marking image with maximum legibility that looks significantly higher quality than the dot markings of other systems.

The BenchScribe really comes into its own when marking steel, aluminium, stainless steel or coated surfaces. It delivers uniform, permanent marking and is also an extremely economical and safe alternative to lasers, as no laser class, extraction technology or special protective environment is required.

Intuitive programming via the 4000 control system or Traceable-IT

The BenchScribe can be programmed quickly and conveniently – depending on your requirements:

- via the integrated Röltgen 4000 control system, or

- via the PC-based Traceable-IT software

Layouts can be created, adapted and saved without the need for additional software knowledge.

Technical data of the scribe marker

Control

- 10.4″ touchscreen (industrial quality)

- Up to 1350 layouts can be stored

- Connections: 1 × USB-A, 1 × USB-B, 1 × RS232

- Digital I/O for machine integration

Software functions

- Font heights from 0.55–99.9 mm (0.13 mm increments)

- Adjustable embossing force and thus variable embossing depth

- Various fonts

- Marking at any angle

- Marking at any radius (e.g. pipes, curved surfaces)

- Automatic serial numbering

- Vector graphics & logos (.plt / .hpgl)

- Real-time & date marking

- Mirror writing

- Password protection

- Test run function

- Multiple menu languages

Optional extensions (some subject to additional charge)

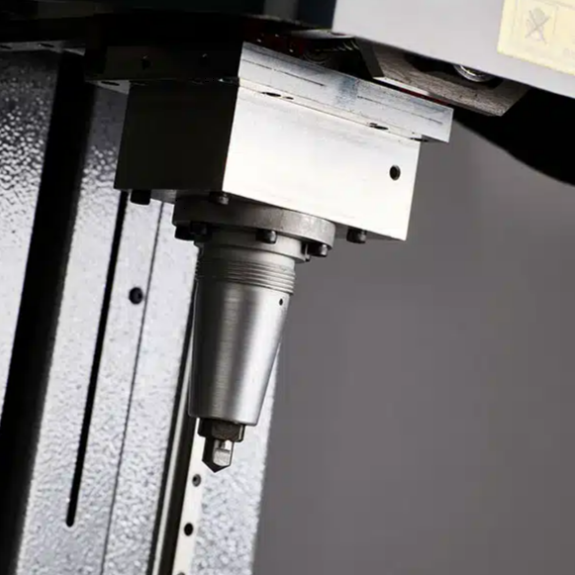

- Light Scribe (diamond stylus) for fine, delicate lines

- Medium Scribe (carbide pen) for deeper, more robust markings

- Partial head for radial marking of pipes or cylinders

- Electric Z-axis for automatic height adjustment

- Autosense – automatic distance detection between workpiece and needle

- Pneumatic depth marking for particularly deep lines

- VeriSmart camera & software for immediate data matrix verification

- TCP/IP Ethernet connection

- Windows software Traceable-IT

- Magnetic or vice clamping systems

- Manual and automatic embossing devices with magazine

These options enable flexible applications from single parts to series production.

Weight

- Marking head with Z-axis & table: 34 kg

- Control: 5 kg

Power supply

- 110–230 V

- 50–60 Hz

Available marking areas

- 100 × 100 mm

- 150 × 150 mm

- 300 × 150 mm

This means that the scribing marker can efficiently cover both compact components and larger parts.