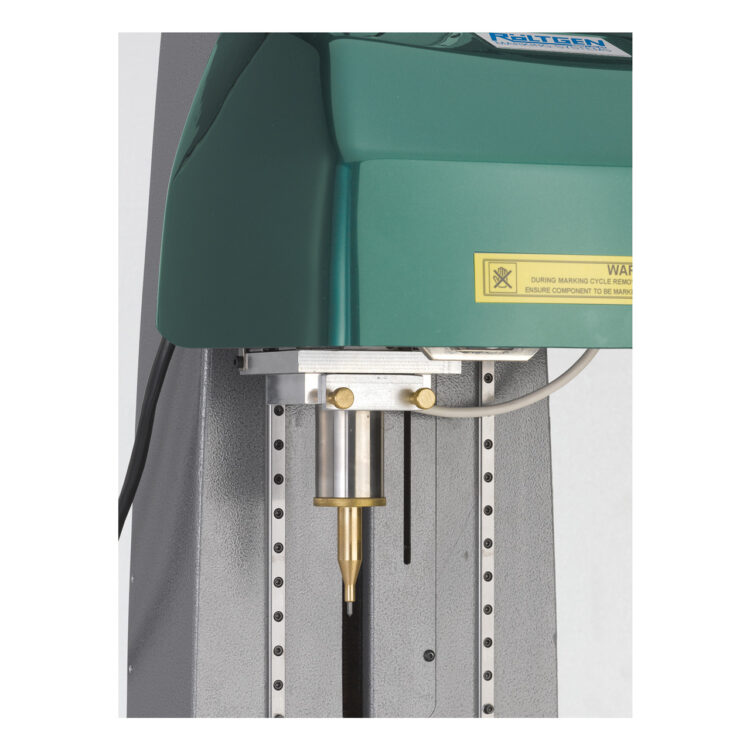

Marktronic BenchDot 4000

The BenchDot 4000 dot peen marker represents the next stage in the development of the successful Marktronic series and sets new standards in professional industrial dot marking. Thanks to the use of particularly high-quality components such as ball screws, double linear guides and precision-ground bearing sets, this system achieves exceptional marking quality – even under demanding conditions and in continuous operation.

At the same time, the machine remains extremely robust and durable. This makes the BenchDot 4000 one of the most reliable dot markers on the market and even meets the requirements of industries that set the highest standards – including approvals from Rolls-Royce.

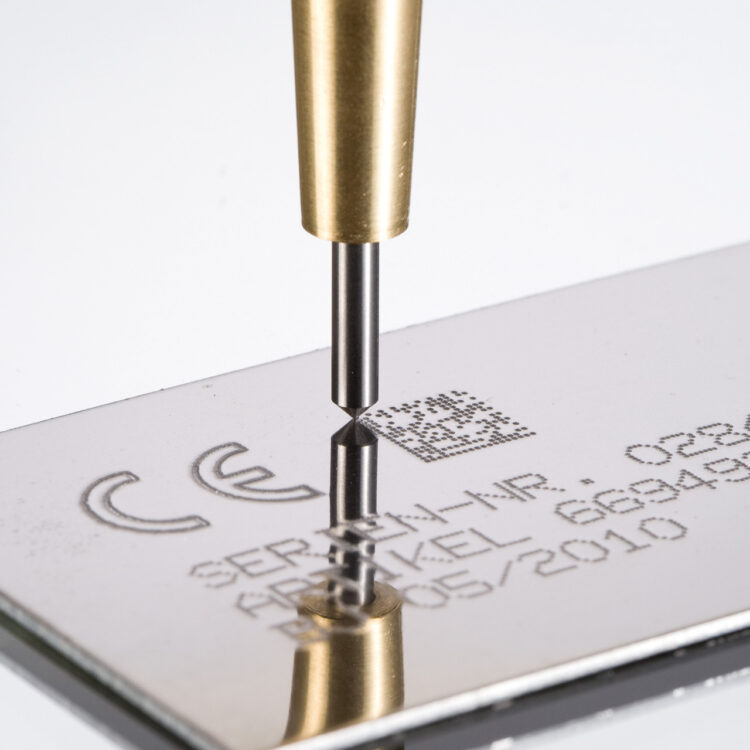

Precise dot marking – even on hard materials and uneven surfaces

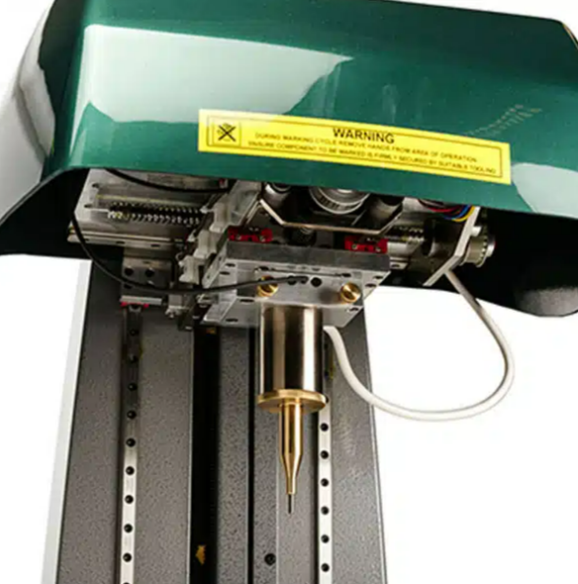

Inside the BenchDot 4000 dot peen marker is a powerful solenoid drive that causes a carbide stylus to vibrate at high frequency. This creates precise dots in the material, which together form the marking.

Thanks to this technology, the machine can:

- Mark materials up to 62 HRC (800 HV) with ease

- Process smooth and uneven surfaces without any problems

- Automatically compensate for height differences of ± 4 mm

- Even reach hard-to-access areas safely

This makes the BenchDot 4000 needle marking machine perfect for companies that place the highest demands on durability, precision and repeatability.

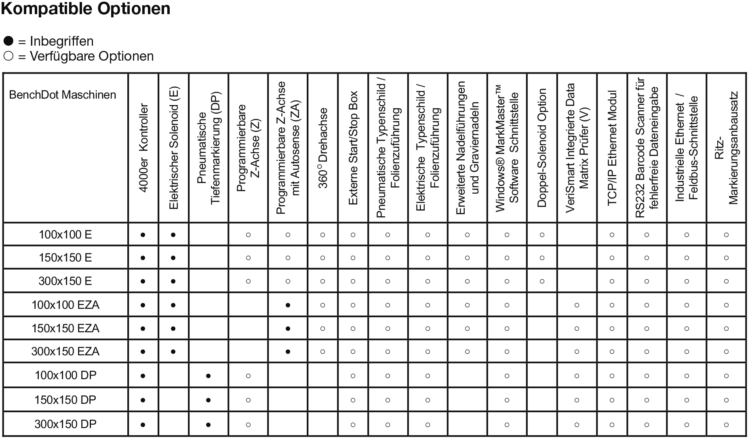

Complete system – modularly expandable

The BenchDot 4000 comes with:

- the high-precision marking head

- a manual Z-axis with a stable work table

- the industrial-grade control system

- a robust connection cable

On request, we can also develop customised devices that can be seamlessly integrated into your production processes. Alternatively, mobile dot markers or permanently installed marking heads are available – ideal for automated production lines.

Powerful control system & intelligent software – maximum control for every marking

Control system (industry standard)

- 10.4″ touchscreen with intuitive user interface

- Memory for up to 1,350 layouts

- USB-A, USB-B and RS232 interface

- Digital I/O for machine integration

Software functions

The software offers everything that modern production processes require:

- Font heights from 0.55–99.9 mm in 0.13 mm increments

- Adjustable embossing force and depth

- Freely rotatable labelling (0–360°)

- Arched and circular markings

- Serial numbers & variable data

- 2D data matrix codes

- Vector graphics and logos (.plt/.hpgl)

- Real-time and date marking

- Mirror writing

- Password protection

- Test run function

- Multilingual menu navigation

This results in clean, deep and absolutely reproducible markings – even with the finest details.

Optional extensions for the highest demands

The BenchDot 4000 needle marker can be expanded modularly and perfectly adapted to your process. Among other things, the following are available:

- Needle lengths: 50 mm, 100 mm or 150 mm

- Different grinding angles (including ASME specification)

- Part head for radial pipe marking

- Electric Z-axis for automatic height adjustment

- AutoSense – automatic distance detection between workpiece and needle

- Pneumatic depth marking for particularly deep, permanent embossing

- VeriSmart camera incl. software for direct data matrix checking

- TCP/IP Ethernet

- Windows software Traceable-IT

- Magnetic or vice clamping systems

- Automatic marking devices

- Diamond scribing head (pneumatic) for particularly fine lines

This makes the BenchDot 4000 dot peen marker a future-proof, highly flexible system that meets every marking requirement in industrial environments.

Technical data – designed for maximum performance

Weight

- Marking head incl. Z-axis & table: 34 kg

- Control: 5 kg

Power supply

- 110–230 V

- 50–60 Hz

Available marking areas

- 60 × 60 mm

- 100 × 100 mm

- 150 × 150 mm

- 300 × 150 mm

Conclusion – one of the most precise and robust dot marking systems on the market

The BenchDot 4000 offers:

- maximum precision

- extreme robustness for 24/7 use

- enormous flexibility thanks to modular options

- state-of-the-art software

- exceptional marking quality even on hard materials

This makes it the ideal choice for companies that value permanent, clean and standard-compliant markings – and are looking for a solution that will work reliably for many years to come.

View in catalog