Embossing tool DK12 / DK18

The DK12 or DK18 embossing tool for machine tools was specially developed for permanent workpiece marking directly during the machining process. Right from the very first step, the embossing tool for machine tools ensures precise, clean and geometrically accurate marking – without additional work steps or external marking stations.

Since the marking is fully integrated into the normal production process, the system significantly reduces both marking costs and the risk of operating errors. At the same time, users benefit from high process reliability and repeat accuracy.

Versatile embossing tool for CNC and conventional machine tools

The embossing tool for machine tools is suitable for both modern CNC machining centres and classic turning, milling and drilling machines. Thanks to its robust design and flexible mounting options, the embossing tool can be easily integrated into a wide variety of machine environments.

Suitable machines:

- CNC machining centres

- CNC turning centres

- Manual lathes

- Milling machines

- Drilling machines

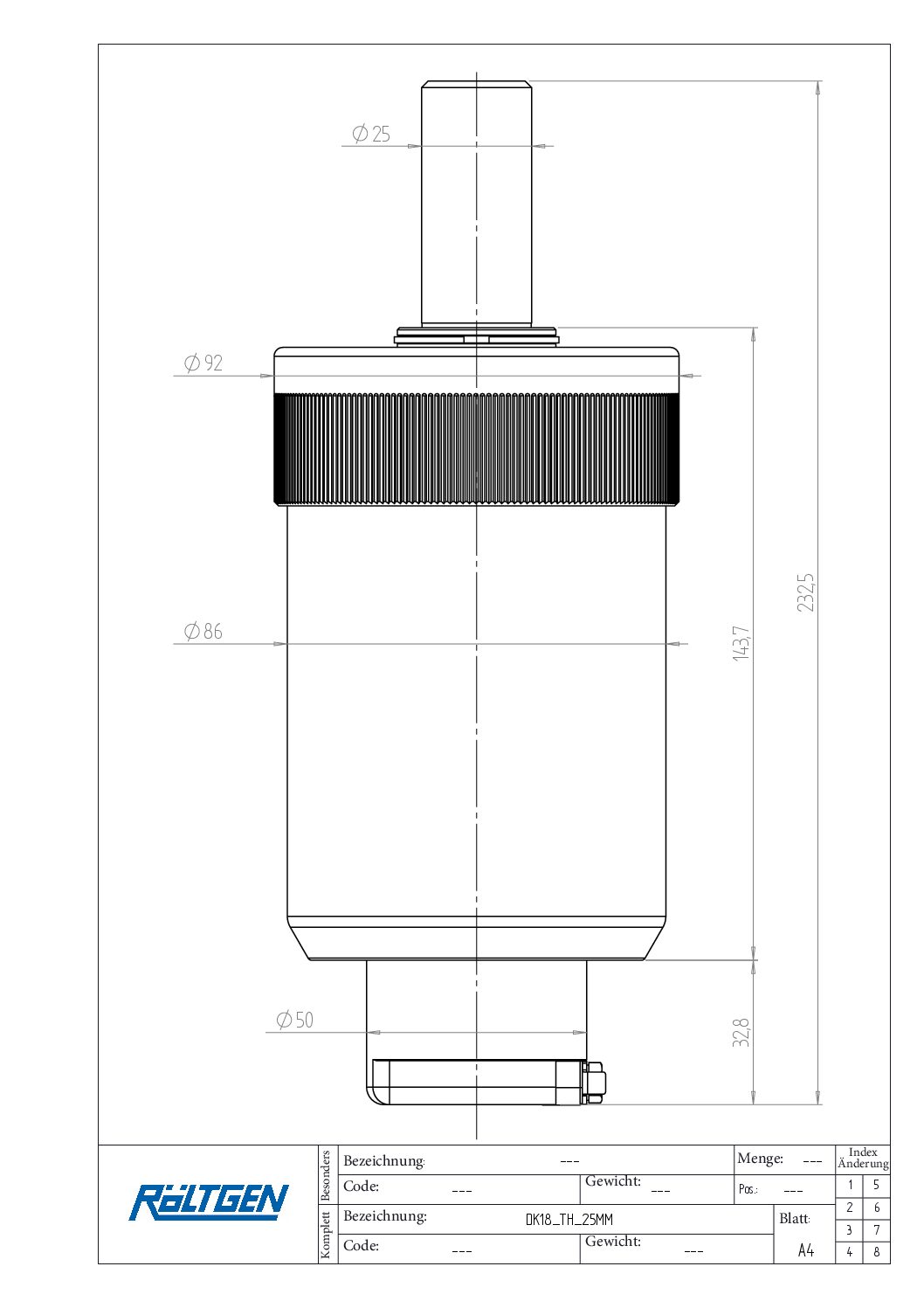

Available shank sizes of the embossing tool for machine tools

- Ø 20 mm

- Ø 25 mm

- ISO 40 / ISO 50

- BT 40 / BT 50

The integrated type holder allows the use of steel types or customer-specific stamps. Optional type holders are also available to further increase flexibility for changing marking requirements.

Economical embossing tool for industrial marking

Thanks to its simple operation, high efficiency and attractive price-performance ratio, this embossing tool for machine tools is one of the most economical solutions for the industrial direct marking of workpieces.

Advantages of the embossing tool for machine tools

- Easy positioning in the tool magazine or turret

- No collision with machine parts or workpieces

- Multiple characters possible per marking process

- Letters and numbers up to 15 mm font height (depending on material)

- Uniform, adjustable marking depth

- High repeat accuracy of the marking position

- Quick tool change during series or product change

- Effective sealing against coolant, oil and chips

How the embossing tool for machine tools works

The marking process is deliberately simple and reliable:

- The desired letters or numbers are inserted into the type holder.

- The user then clamps the embossing head into the machine’s tool holder.

- During machining, the tool holder presses the embossing head against the workpiece in a controlled manner.

- An internal spring assembly is tensioned and releases when the set force is reached.

- The characters are embossed cleanly and permanently into the material.

The embossing depth can be precisely adjusted to the material and marking requirements by turning the head.