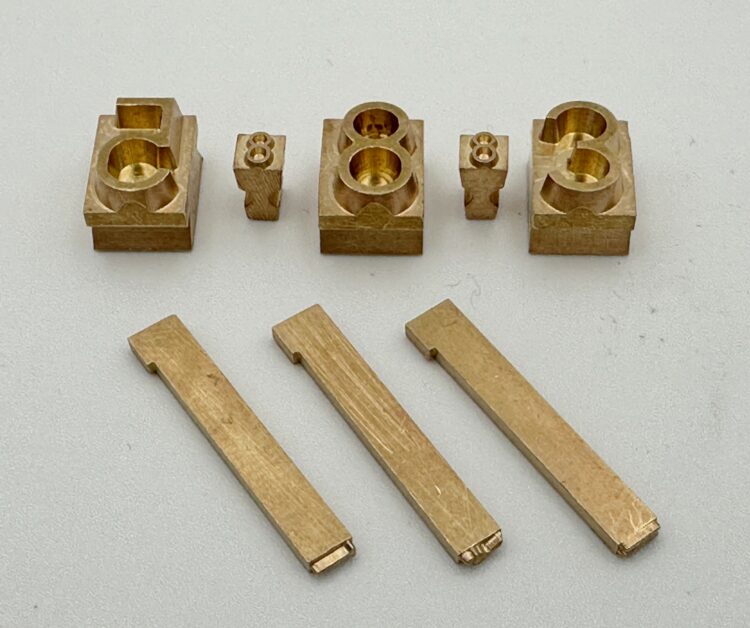

Brass types for hot stamping

Brass embossing dies are the first choice for hot embossing applications. This is because brass absorbs heat particularly quickly and stores it efficiently. As a result, brass embossing dies reach the required working temperature within a very short time. Consequently, they are ready for use almost immediately.

Moreover, the excellent thermal conductivity of brass ensures precise heat transfer during the embossing process. Therefore, the material delivers clean, sharp and durable embossing results. Even with large production volumes or demanding materials, brass embossing dies maintain consistent quality.

Custom brass embossing dies – tailor-made to your specifications

We manufacture custom brass embossing dies in any required size, shape or design. Each die is engraved exactly to customer specifications. This ensures razor-sharp precision and reliable repeat accuracy in every application.

Possible design options include:

Special fonts and typefaces

Company logos, symbols and graphic elements

Single-line or multi-line text layouts

Complex engravings and fine detail structures

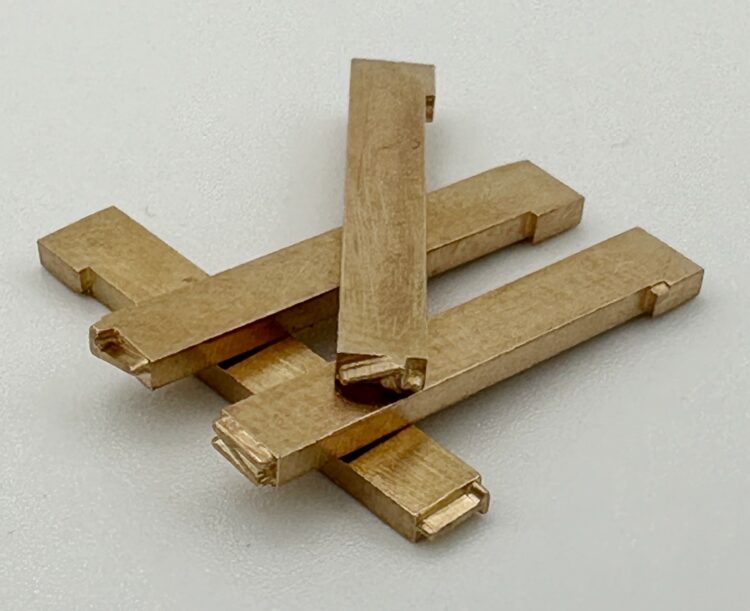

Whether you require individual types, connected type sets or complete stamp plates, we deliver perfectly matched brass embossing dies. Thus, every solution fits your application precisely.

Matching type holders and brass branding irons

In addition, we manufacture a wide range of matching accessories. On request, these include:

Type holders for variable or interchangeable brass types

Brass branding irons for wood marking, leather embossing or plastic embossing

Together, these components form a coordinated complete system. As a result, the solution can be used immediately. This makes it ideal for industry, trade, manufacturing and advertising technology.

Non-binding quote – quick and easy

Finally, requesting a quote is straightforward. Simply send us your ideas, samples, drawings or digital files. Based on this information, we will prepare a tailor-made, non-binding offer.

Additionally, our experienced team is happy to advise you. We support you with design selection, material thickness, engraving depth and the optimal manufacturing process. Therefore, you receive a solution that is both technically and economically optimized.