Universal spring-loaded impact press

Many workpieces need to be processed during manufacture or further processing. This includes operations such as embossing, straightening, deburring, riveting, punching, bending or flanging. Employees often still perform these steps by hand. However, a universal spring-loaded impact press offers a much more efficient and significantly more precise alternative. It supports the user and ensures reproducible results at the same time.

How a spring impact press works – simple, powerful and controllable

A spring impact press uses the interaction of the impact spring and impact pin to generate high forces. The user first tensions the spring using the hand lever. They then trigger the impact in a targeted manner. This causes the impact pin to transfer the force directly to the tool.

As the impact moment occurs very quickly, high forces are generated that are ideal for many machining processes. In addition, the impact force can be continuously adjusted, as you can adjust the spring tension at any time. The effort required by the operator remains low, as they only have to perform the tensioning and feeding process. The actual impact energy is provided by the spring.

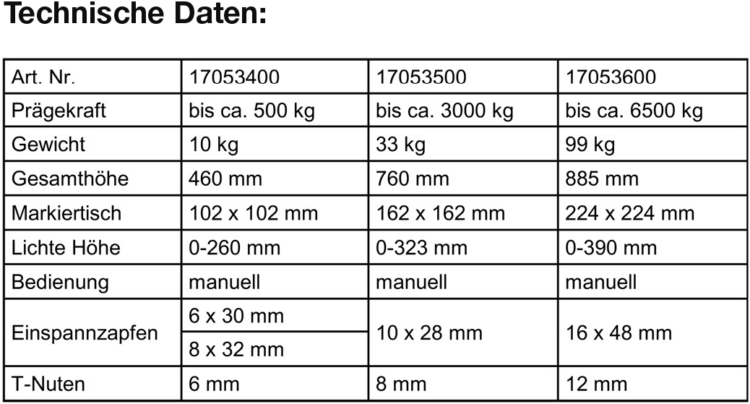

Three versions in one for different applications

The universal spring impact press is supplied with three different springs. Each tension spring has a specific force range so that you can adjust the impact force as finely as possible on the press. This makes the model suitable for light, medium and even demanding machining operations. This versatility makes the press a practical solution for many industrial sectors.

Your advantages at a glance

- Robust and durable: The press can withstand high loads and is therefore suitable for continuous use.

- Easy to operate: Handling remains straightforward even with frequent workpiece changes.

- Infinitely adjustable impact force: You can adjust the power to suit the material and task at any time.

- Low effort required: The spring provides the necessary impact energy, not the operator.

- Versatile: Ideal for embossing, riveting, punching, bending, deburring, flanging and similar tasks.

- Cost-effective alternative: A manual impact press operates independently of electricity, pneumatics or hydraulics.

- Reliable and simple: The robust mechanics ensure consistent results without complex adjustments.

Conclusion – a simple yet powerful solution

The universal spring-loaded impact press supports any operation that requires a manual but powerful and precise press. It offers a clear structure, intuitive operation and reliable performance. This makes it suitable for workshops, assembly areas, metalworking and many other industrial applications.

View in catalog