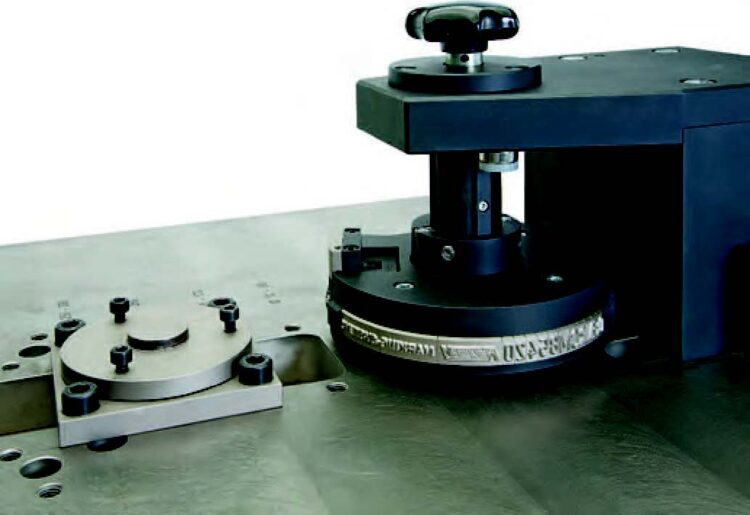

Universal table roll-off embossing machine

The PR 1126 table-top roll embossing machine is a robust, durable and versatile solution for roll-off embossing of workpieces with diameters ranging from 18 to 400 mm. Thanks to its solid construction, it is ideal for continuous industrial use. It also enables clean, uniform and permanently legible marking – on both round and straight components.

Typical areas of application include the marking of rods, cylinders, brake discs, pipe sections, fittings, round blanks, perforated discs, shafts and many other cylindrical or rotating workpieces.

Flexible marking with roll-off type holders

The PR 1126 works with a single or multi-line roll-off type holder that can be quickly and easily loaded with segment steel types. This allows you to flexibly compile texts, batch numbers, logos, material specifications or serial numbers.

Advantages of the type holder:

- Individual types or complete block types can be used

- Extremely flexible for changing markings

- Font heights up to 10 mm according to customer requirements

- Ideal for serial marking and component identification

These features make the machine particularly suitable for companies that frequently mark different workpieces.

How the table-top roll embossing machine PR 1126 works – simple, fast and reliable

Operation is intuitive, allowing the user to achieve precise results quickly.

1. Load the type holder

The type holder is loaded with the appropriate types over 180°. The flattened area faces away from the workpiece.

2. Insert the workpiece

The component is placed between the counterpressure rollers and the type holder.

3. Make the settings

- The embossing depth is set using the right-hand crank.

- The height clearance is adjusted using the rotary knob above the type holder. A tool-free adjustment is available on request.

4. Start embossing

After the two-hand operation is triggered, the type holder rotates once through 360°. During this movement, it rolls the text evenly into the workpiece.

5. Automatic stop

After completing a full rotation, the machine stops automatically. The workpiece can then be removed immediately and the next embossing cycle can begin.

This method ensures precise roll-off embossing, prevents double strikes and creates a clearly legible result on every component.

Technical data of the PR 1126

Feature Value

Embossing range 18 – 400 mm Ø

Height adjustment 0 – 75 mm

Font length up to 500 mm

Font height max. 10 mm

Output approx. 700 pieces/hour

Voltage 380 V, 50 Hz

Machine dimensions 1100 × 750 × 1100 mm

Weight approx. 250 kg

These performance data clearly show that the PR 1126 is designed for high quantities and demanding industrial applications.

Typical applications

The PR 1126 is ideal for permanent marking of:

- Bars and round material

- Cylinders and pipes

- Brake discs, perforated discs and flanges

- Fittings and fixtures

- Turned parts of various sizes

- Blank discs, bushings and tool components

- Socket wrenches and similar workpieces

It thus covers a very wide range of applications in the metal, automotive, hydraulic and supply industries.

Optional accessories – for maximum flexibility

✔ Roll holder Ø 156 mm

✔ Height adjustment via rotary knob

✔ Aluminium profile under-table

✔ Fixed roll stamp for special embossing

✔ Extended embossing area for particularly large workpieces

These accessories allow you to adapt the machine precisely to your production requirements.

Conclusion – the table-top roll embossing machine PR 1126 for precise and permanent circular markings

The PR 1126 tabletop roll-off marking machine combines high stability, flexible text design and precise roll-off technology. This makes it ideal for companies that want to mark round or cylindrical components on a regular basis. It works cleanly, quickly and extremely reliably – even in daily continuous use.

View in catalog