Pneumatic hand stamping device RBM

Our RBM series pneumatic hand stamping devices are among the most flexible solutions for hand stamping in industry, workshops and trade. They operate without recoil, allowing you to stamp in a controlled and clean manner at all times. In addition, the devices require only low contact pressure, which significantly increases working comfort and enables repeatable results.

As the embossing power can be continuously adjusted, you can adapt the pneumatic stamping device precisely to the respective material and the desired marking depth. This makes the RBM devices ideal for aluminium, steel and many other materials.

Advantages of the RBM hand stamping devices

Thanks to their ease of use, high flexibility and quick tool change, the RBM models are among the most popular solutions for mobile or stationary hand stamping. You benefit from:

- Uncomplicated handling

- Quick change of embossing tools and inserts

- Precise, clean and energy-saving stamping

- Versatile applications in daily production operations

Whether controlled grain, numbering, type stamping or the application of material markings – RBM devices can be used to reliably perform many marking tasks.

The RBM models at a glance

Group 1707 – RBM 10

- Length: approx. 260 mm

- Weight: approx. 520 g

- Ideal for fine markings and light stamping work

Group 1708 – RBM 22

- Length: approx. 300 mm

- Weight: approx. 980 g

- Perfect for typical industrial environments and versatile embossing applications

Group 1709 – RBM 25

- Length: approx. 350 mm

- Weight: approx. 1,660 g

- Suitable for stronger embossing and larger numbers of characters

Various tools – maximum flexibility thanks to quick tool changes

The illustrations show which tools can be clamped into the RBM devices:

- RBM 10: Centre punch attachment for dot marking

- RBM 22: Type holder with interchangeable steel types

- RBM 25: Embossing unit with adjustable wheels for multi-digit markings

Tool changes are quick and easy. This allows you to effortlessly convert the pneumatic stamping device for new tasks.

Optional version for plant engineering

On request, we also supply RBM devices as built-in versions with:

- Pneumatic cylinder

- Built-in frame

- Connections for integration into production systems

This allows the devices to be easily integrated into semi-automatic or fully automatic production lines.

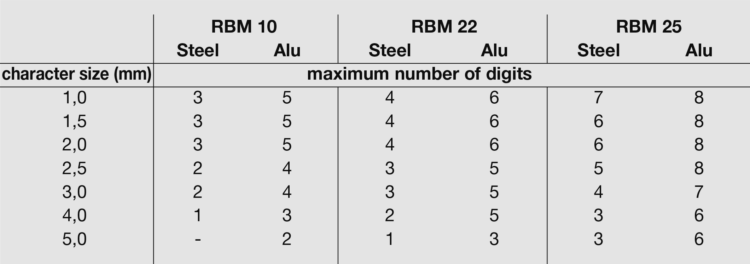

Stamping performance – example values for practical use

The actual performance depends on the material and the engraving used. The following guideline values serve as a reference:

Example:

- Device: RBM 22

- Font height: 3.0 mm

- Material: steel

- Maximum number of characters: 3 characters

We would be happy to work with you to determine more precise results in an embossing test.

Conclusion – Pneumatic hand stamping device for precise and flexible markings

RBM hand embossing devices combine:

✔ Easy handling

✔ Pneumatic support for energy-saving work

✔ Quick tool change

✔ Precise and permanent markings

This makes them perfect for businesses that need reliable hand stamping – whether directly at the workplace, on the move in the service area or integrated into a production plant.

We would be happy to demonstrate the right device for you. Contact us – we will advise you personally.

View in catalog