Marktronic CNC dot peen marker

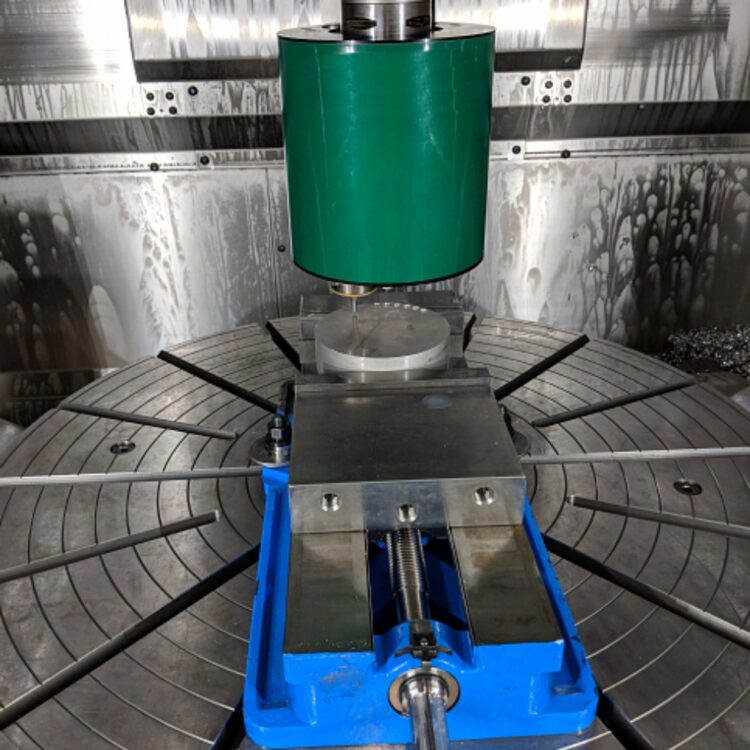

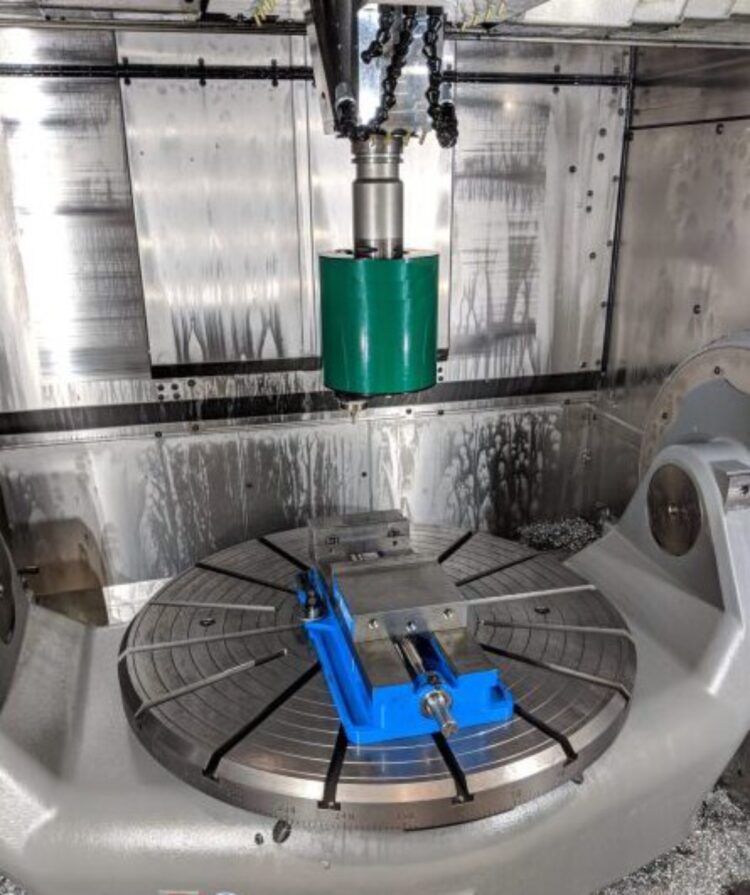

The Röltgen CNC marking device is an advanced dot marking device or needle embosser that can be seamlessly integrated into almost any existing CNC machine. It enables dot marking of components of all shapes and sizes – without an additional workstation, without re-clamping and without interrupting the manufacturing process.

Whether serial numbers, 2D data matrix codes, logos or alphanumeric information: this system ensures permanent, unique and standard-compliant marking directly in your machine. For many manufacturing companies, it is therefore one of the most efficient solutions for industrial traceability and embossing on steel and other technical metals.

Wireless, flexible and easy to integrate – ideal for any CNC environment

The Röltgen CNC marking device is battery-powered and has integrated WiFi control. This allows it to be clamped into different tool holders – e.g. HSK, Capto or CAT – and used like a regular tool in the turret or tool magazine.

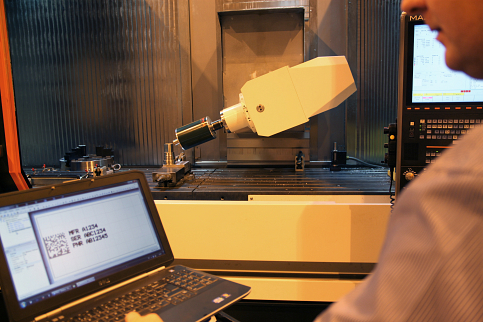

Programming and data transfer are conveniently carried out via PC or CNC control. This makes this system a particularly automated tool for modern production lines.

Less waste – marking without workpiece transport

In many manufacturing companies, damage and waste are mainly caused by the handling of components after machining.

With the Röltgen CNC needle marker, this risk is completely eliminated:

✔ Inline marking directly in the machine

✔ No transport to separate marking stations

✔ No damage due to re-clamping or handling

✔ Ideal for limited space conditions

This allows you to significantly increase process reliability, efficiency and repeatability.

Dot marking according to international aerospace standards

The marking head generates a sequence of precise individual dots that together form the marking. This method is particularly suitable for:

- Safety-relevant components

- Applications with minimal surface alteration

- Parts that must meet strict aviation standards

Dot marking causes minimal material stress and is therefore an ideal solution for marking on steel, titanium and hardened metals.

The removable battery allows continuous operation with an optional replacement battery, while an automatic shut-off function saves energy and maximises battery life.

Windows-based software – intuitive operation & maximum flexibility

The WiFi-based user interface allows quick loading, creation and management of marking layouts. The integrated drag-and-drop editor supports:

- Various fonts

- Arc marking

- Logos

- Alphanumeric texts

- Data matrix codes

- Automatic serial numbering

- Duplicate protection

The adjustable embossing depth allows adaptation to different materials and hardnesses – up to 62 HRC (800 HV).

Layouts can be called up directly via CNC programmes, so that marking is triggered fully automatically during the machining process.

Technical data at a glance

Battery & operation

- Removable 36V 2.0Ah Li-ion battery

- Over 3 hours of continuous marking

- Automatic shutdown when inactive

Communication & programming

- WiFi interface for programme upload, selection & live control

Marking area

- 50 × 25 mm

Protection class

- IP53 (suitable for harsh industrial environments)

Compatible tool holders

- HSK, Capto, CAT – others available on request

Dimensions

- Diameter: 152 mm

- Length without tool holder: 221 mm

- Weight: 6.5 kg

Marking formats & characters

- Standard character sizes: 0.15–99.9 mm (increments of 0.15 mm)

- Formats: 5×7, 7×9, Varidot

- HPGL & BMP logos

- TrueType fonts

Marking mechanism

- Electromagnetic coil

- Programmable depth adjustment

- Suitable for metals up to 62 HRC / 800 HV

The CNC marking device from Röltgen – the ideal solution for automated inline marking

This system is perfect for companies that:

- Want to mark automatically

- Want to optimise inline processes

- Need dot marking on steel without an additional workstation

- Want to improve the traceability of their components

- Want to reduce waste through handling